SERIGRAPHY

The color is imprinted through a micro-perforated film, through these holes the pigment is deposited on the surface following the required customization.

PAD PRINTING

With this technology the design is transferred to the product through a soft pad that is loaded with the pigment.

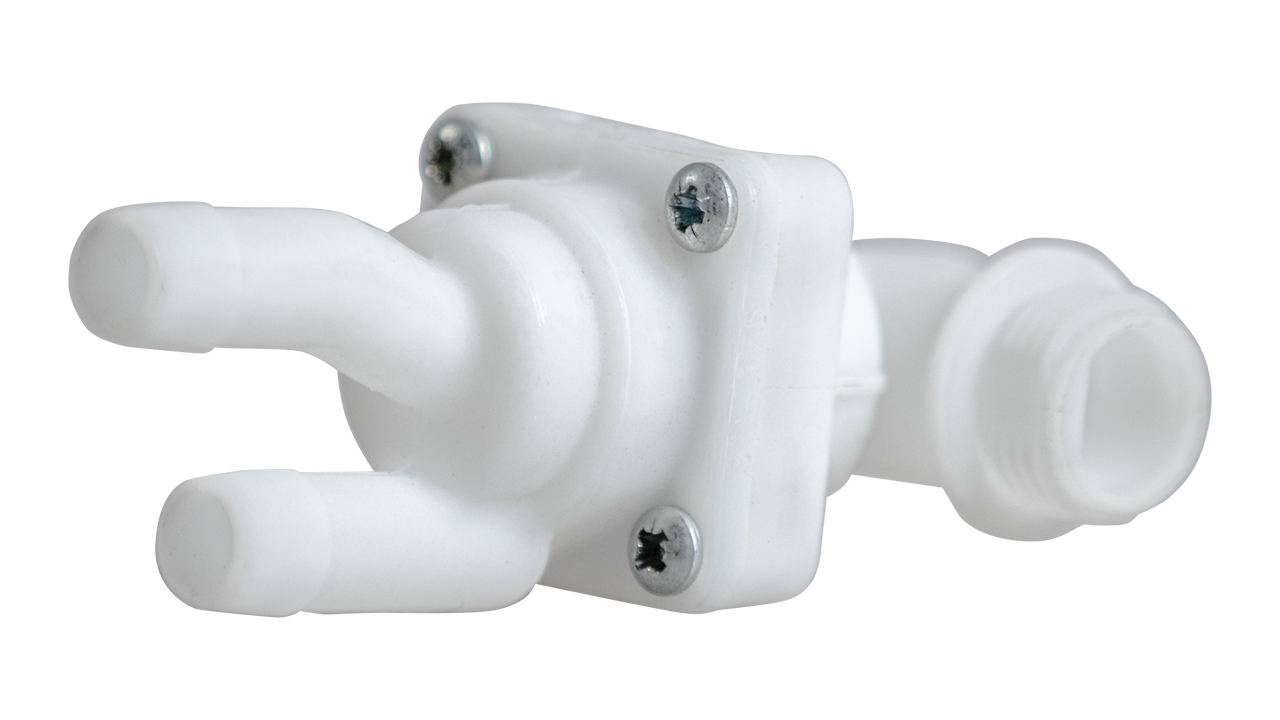

ASSEMBLY

Thanks to our operators with the supervision of the technicians we can assemble the products for both small and large productions.

The assembly can take place through welding, mechanical or pneumatic unions.

Each project is designed and then made “tailored” for this we can achieve the best value for money.

ULTRASONIC WELDING

Ultrasonic welding allows the union of two plastic bodies through vibration with ultrasonic sequence.

One of the two parts starting the intense vibration generates heat and consequently the thermoplastic materials merge ensuring a proper assembly.

PACKAGING

We can make a suitable packaging for every product made, an aspect of primary importance.

One of the necessities is to guarantee the protection of the goods, we try through a careful appraisal the just economic balance between cost and service, selecting suitable materials for this purpose.

In recent years we offer our customers environmentally friendly packaging easy to recycle, an increasingly important aspect.